Geo Refining using EM Screens

Stacking Display Screens; Architect True Value

Stacking Display Screens; Architect True Value

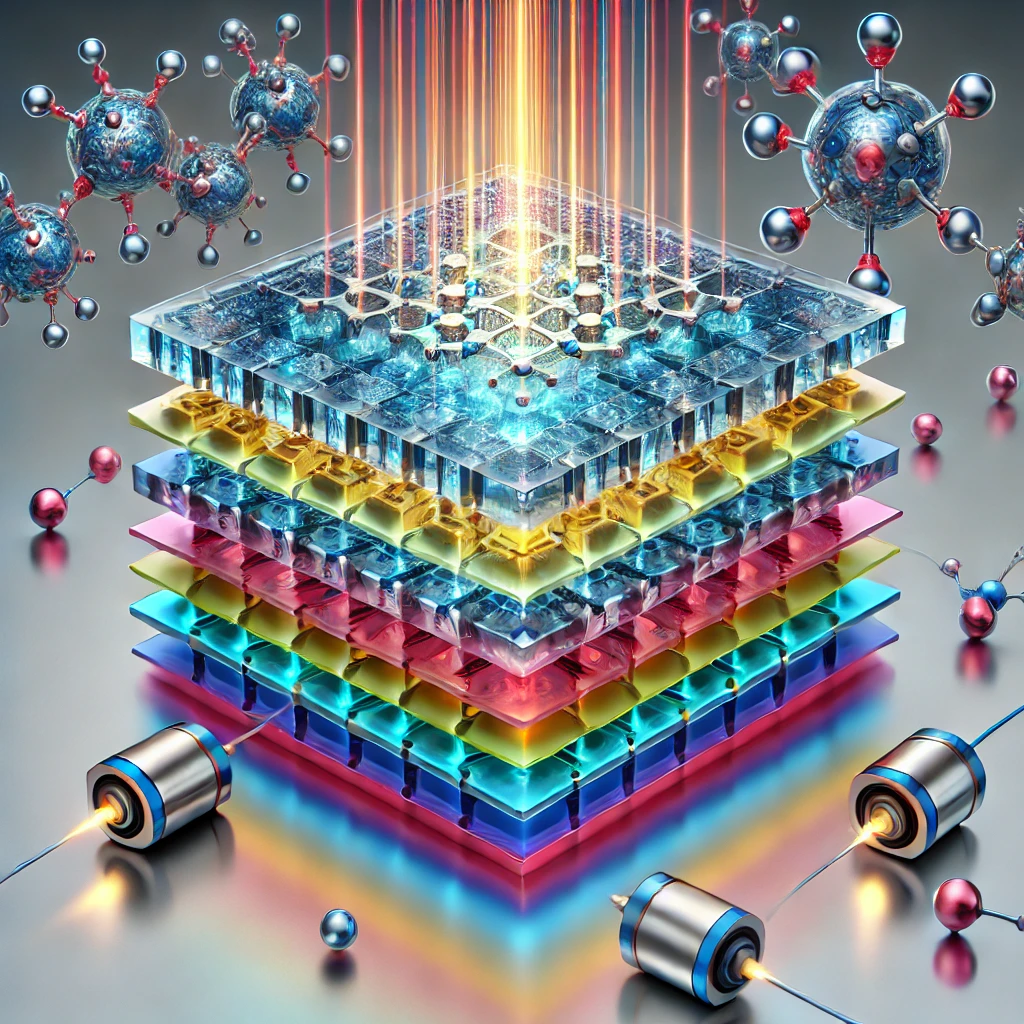

The EM Screens like slides can be stacked together towards an EM Drive system, transforming them into dynamic molecular formulation pipelines. Each screen could be chemically enhanced to facilitate electromagnetic field interactions, guiding molecules through structured pathways where their properties can be systematically altered. Molecular interaction within the screens is guided by precise energy thresholds, enabling polarity alignment and targeted bonding. Feedback loops from embedded sensors ensure real-time recalibration, adapting to molecular variability and maintaining process integrity. This process integrates the screens computational capabilities with their ability in molecular conduits. OLED-generated energy modulates molecular bonds for sorting or processing.

By leveraging these features, the an EM screen system can help in so many industries. Controlled flows of distributed molecules organize for intended purpose, perhaps a Chroma block to a distributed Map of the Universe.

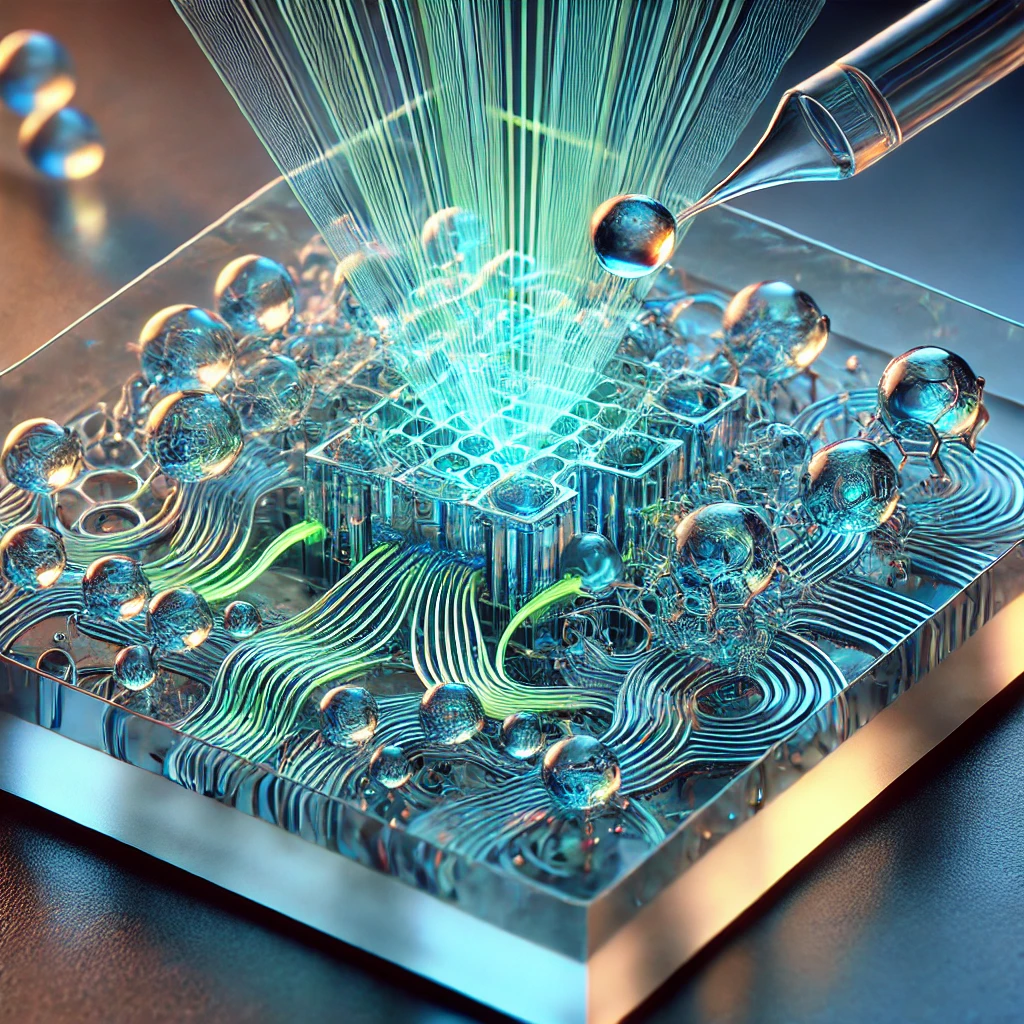

The EM Screen pipeline is built on the principle of task-specific efficiency, ranging screen configurations to match the requirements of molecular processes. This approach ensures that the system is neither overburdened with unnecessary precision nor underpowered for critical tasks, making it both adaptable and cost-effective. Molecules that do not meet process criteria are dynamically rerouted into secondary refinement zones, ensuring optimal output while minimizing waste. This iterative approach adapts to molecular variability, maintaining efficiency across diverse applications.

This modular approach allows the EM Screens to serve a broad range of applications, from high-throughput molecular sorting to precision assembly of advanced materials. By focusing on molecular nodes, the screens ensure that energy and material resources are utilized to their fullest potential. Refining molecules for high-efficiency battery materials. Customizing molecules for targeted drug delivery in medical applications.

OLED technology, at the heart of EM Screens, serves as a dynamic gearset for molecular modulation. By leveraging OLED's ability to emit phase-coherent light and modulate energy thresholds, the system enables:

These features transform OLEDs into active participants in molecular pipelines, enabling the seamless transition from raw input to precise outputs. By integrating advanced OLED technology, EM Screens transcend traditional display functions, becoming key enablers in refinement and molecular design.

MicroLED technology offers unmatched durability and precision, making it an ideal choice for molecular processing systems requiring resilience under demanding conditions.

MicroLEDs can revolutionize molecular processing and energy systems by enabling:

While MicroLEDs excel in durability and precision, achieving high DPI (dots per inch) for nanoscale molecular arrangements can pose challenges:

As manufacturing techniques advance, MicroLEDs will achieve higher resolutions, expanding their applications in molecular and energy systems. Future developments may include:

MicroLED technology bridges the gap between durability and precision, making it a cornerstone for next-generation EM screens in molecular and energy applications.

At the core of the EM Screen is the use of advanced display technology such as OLEDs, microLEDs, or transparent electrode layers—as computational substrates. These screens chemically altered for enhancement and are then stacked slides, with each layer contributing to both data visualization and processing. Each screen functions as both a computational and physical processing node, managing molecular data and directing energy flows in unison. This dual functionality enhances precision and streamlines processes from input to output.

Molecular interaction within the screens is guided by precise energy thresholds, enabling polarity alignment and targeted bonding. Feedback loops from embedded sensors ensure real-time recalibration, adapting to molecular variability and maintaining process integrity. Molecules flow down carefully controlled fields in a catalytic converter of atomic organization serve as programmable spaces for molecular development.

Combining MicroLED arrays with CRT ion drives introduces a powerful synergy for molecular and energy systems. CRT ion drives, placed strategically at the corners of the system, act as torque amplifiers, enabling precise control over molecular positioning and energy distribution.

By incorporating CRT ion drives, the system gains:

The addition of CRT ion drives enhances the molecular pipeline by:

The integration of CRT ion drives with MicroLED systems opens new avenues for:

The EM Screens enable groundbreaking precision in identifying and refining elemental arrangements. By combining advanced OLED technology, volumetric sensing, and phase-coherent electromagnetic fields, the system creates an environment where molecular and atomic structures can be meticulously analyzed and modified.

This system employs interference patterns and molecular energy state detection to visualize and refine elemental arrangements. The precision provided by the EM Screen pipeline transforms raw inputs into refined outputs optimized for various industrial and scientific applications, such as:

By leveraging OLED-generated energy modulation and volumetric sensing, EM Screens become powerful tools for crafting precise elemental arrangements, unlocking a new era of material innovation and field modulation precision.

EM Screens serve as dynamic nodes within the Unison Lattice, enabling precise control over energy distribution and molecular refinement. Their modular design allows them to adapt to diverse environments, ensuring that energy flows remain coherent and materials are optimized for structural and functional needs.

Within the Unison Lattice, EM Screens provide:

The EM Screen Chroma Processor represents a paradigm shift in computational design, combining stacked displays, volumetric sensing, and energy routing into a single, cohesive system. By reimagining screens as active participants in computation and manufacturing, this innovation opens the door to new possibilities in technology and science.

As we pioneer the integration of EM Screens into molecular pipelines, we invite innovators and researchers to join this transformative journey. Together, we can unlock new frontiers in computation, energy, and material science, shaping a future defined by sustainable innovation.