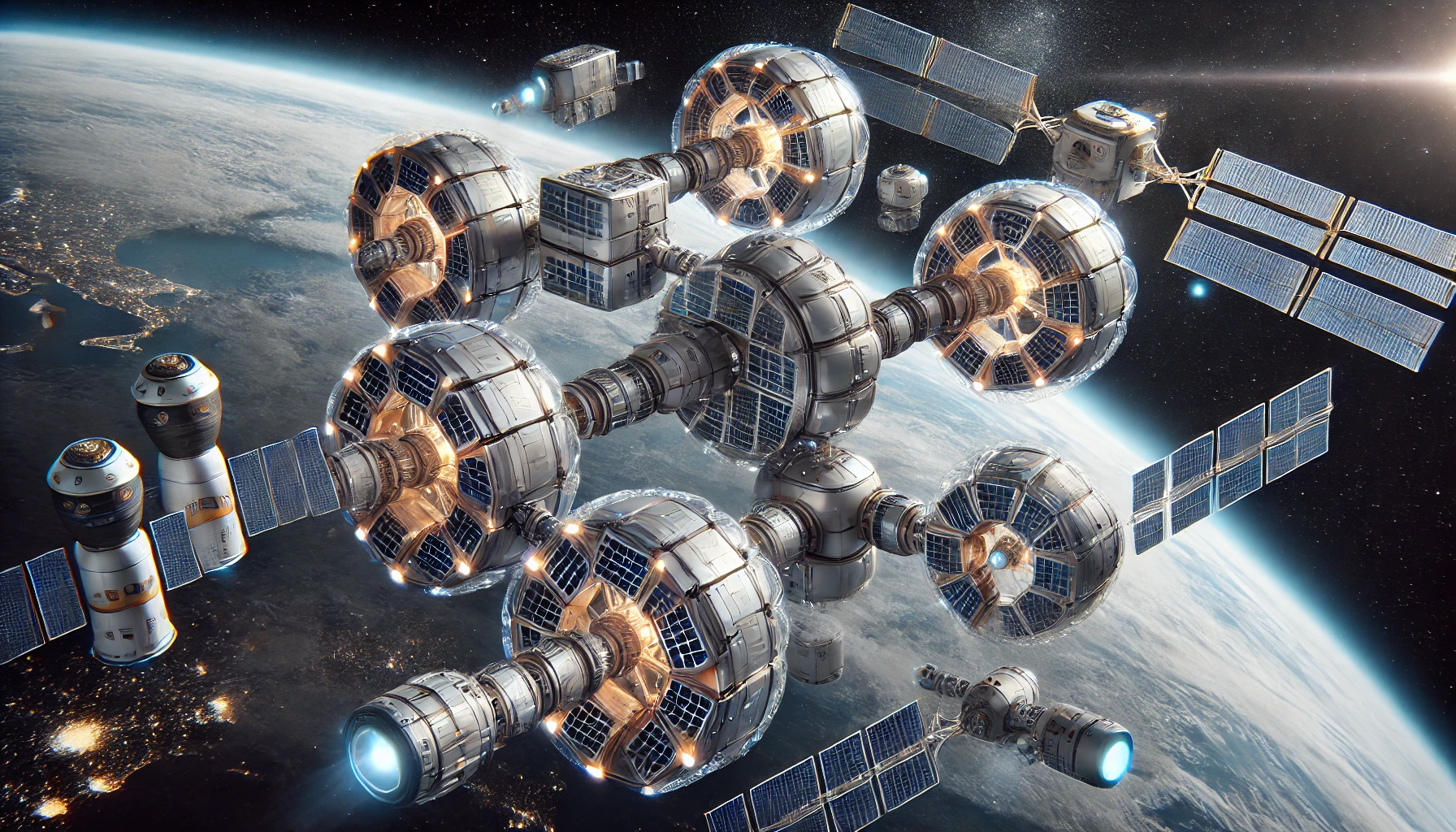

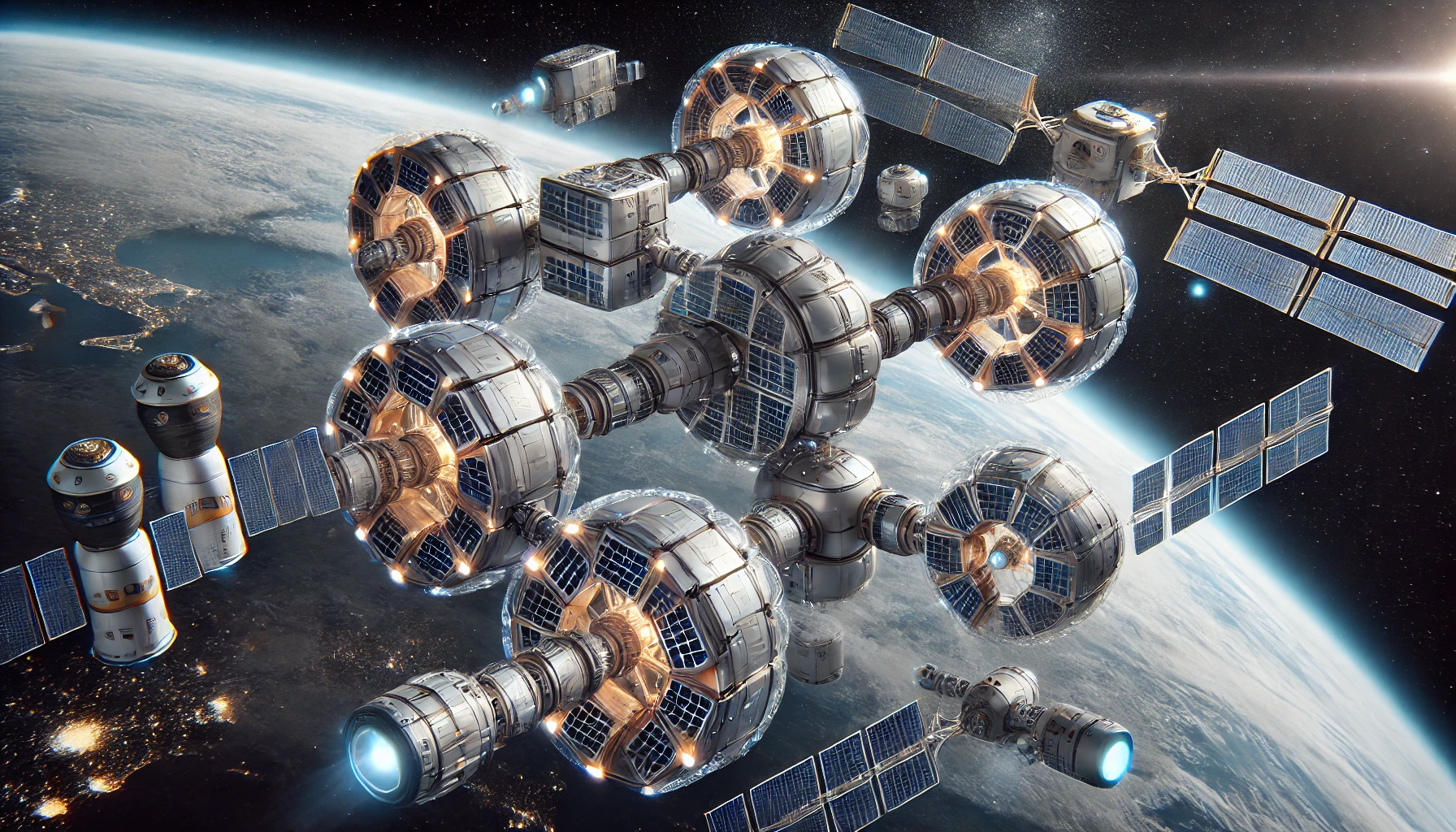

Recycling Satellite (Unison Lattice Box) Creating Processors & Materials

The Satellite Lattice Refinery, known as the Unison Lattice Box, transforms orbital waste and flagged materials into Chroma Spatial Processors (Cubes), revolutionary modular components that redefine how resources are utilized in space.

These processors enable a sustainable and adaptive approach to orbital infrastructure, strengthening communication networks and facilitating material exchange between systems.

Enabling Chroma Spatial Processors in Orbit

The Unison Lattice Box creates Chroma Spatial Processors and enable distribution into orbiting systems. These processors unlock a vast array of functionalities:

- Communication Enhancement: Chroma Spatial Processors serve as dynamic nodes, optimizing signal transmission and data synchronization.

- Material Exchange: Modular and precise, the processors enable the transport, refinement, and assembly of resources across orbital platforms.

- Energy Routing: Acting as efficient conduits, they manage energy distribution with unmatched precision.

- Infrastructure Expansion: The modular design allows for rapid construction and adaptation of orbital habitats and operational hubs.

Sustainable Space Innovation

The Satellite Lattice Refinery ensures that orbital systems evolve sustainably, with each Chroma Spatial Processor contributing to a growing ecosystem of adaptable and resource-efficient solutions.

From recycling space debris to enabling interconnectivity, the Unison Lattice Box represents a bold step toward a self-sustaining future in space exploration.

Material Sourcing and Zero-G Initialization

To kickstart Chroma Cube production in orbit, a strategic combination of Earth-based materials and space-sourced resources can be utilized.

Materials like silicon, lightweight alloys, and superconductors are essential for the MX2 group and can either be launched from Earth or extracted from celestial sources.

- Asteroid Mining: Near-Earth asteroids provide metals like nickel, cobalt, and rare-earth elements critical for Chroma fabrication.

- Lunar Resources: Lunar regolith offers silicon and oxygen for semiconductor and structural applications.

- Earth-Origin Inputs: Lightweight alloys and specialized polymers can jumpstart the process for zero-G manufacturing.

Zero-G factories offer unparalleled advantages for Chroma Cube production:

- Precision Fabrication: Microgravity minimizes structural stress, ensuring defect-free components.

- Energy Efficiency: Materials can be moved and aligned with minimal energy, making large-scale production more sustainable.

- Superior Material Properties: Materials grown or fabricated in microgravity display enhanced characteristics, such as fewer defects and better uniformity.

By utilizing both terrestrial and space-based resources, zero-G factories can rapidly become self-sufficient, producing Chroma Cubes at a scale that supports a wide range of applications, from orbital infrastructure to interplanetary missions.

MX Screening for Spatial Processing

The Unison Lattice Box features an advanced MX screening system, designed to identify and separate valuable molecular groups from orbital debris.

Using electromagnetic grids and precision sorting technologies, the system isolates MX compounds, channeling them toward the MX2 Spatial Processor for refinement and integration into Chroma Spatial Processors.

How MX Screening Works

-

Capture and Fragmentation: Orbital debris is collected using electromagnetic nets and robotic arms, then fragmented into smaller pieces for efficient screening.

-

If people appose beam steering for spherical guided recycling basket ball then it'll have to be bender bender arms.

-

Layered Screening Grids: The system uses multi-layer grids tuned to detect specific molecular signatures.

- Molecular Absorption: MX compounds are absorbed through the grid, while non-MX materials are diverted to alternate channels.

- Selective Permeability: Each grid layer targets different MX compositions, ensuring precise material separation.

-

Channeling Materials: Once absorbed, MX compounds are directed into specialized pathways:

- Primary MX Streams: Raw MX materials for immediate processing.

- Blending Channels: Pathways for combining compatible MX groups to form composite materials.

- Non-MX Diversion: Rejected materials are rerouted for structural applications, insulation, or safe disposal.

-

Dynamic Feedback: Real-time sensors monitor incoming materials, adjusting electromagnetic thresholds to optimize sorting efficiency.

Applications of MX Screening

The MX screening system enables a sustainable approach to orbital resource management by:

- Maximizing Efficiency: Only compatible MX compounds are processed, minimizing waste.

- Repurposing Debris: Non-MX materials are reused for structural or auxiliary purposes, supporting a circular space economy.

- Optimizing Refinement: The isolation of pure MX compounds ensures precision and efficiency in the MX2 Spatial Processor.

The Path to Chroma Spatial Processors

After screening, the refined MX compounds are transported to the MX2 Spatial Processor. Here, advanced molecular alignment and integration processes transform the materials into high-performance Chroma Spatial Processors, ready to power space systems and infrastructure.

Centralized Spatial Processing for Chroma Cube Fabrication

The Unison Lattice Box employs a cutting-edge process to fabricate Chroma Spatial Processors (Cubes) by channeling MX compounds toward a central Spatial Processor.

This centralized system orchestrates the transformation of raw molecular inputs into intricately layered MX2 structures, interlinked for optimal spatial performance and utility.

How the Process Works

-

Directed Molecular Influx: MX compounds are introduced from the sides of the Unison Lattice Box, propelled toward the central Spatial Processor at controlled velocities.

This ensures that materials arrive with the precise energy and alignment needed for structured refinement.

-

Dynamic Organization: As the compounds travel toward the processor, they are organized into MX2 layers by the interaction of electromagnetic fields and energy pulses.

These fields align the molecules into optimized configurations, ensuring structural integrity and desired properties.

-

Layer Interlinking: The central Spatial Processor integrates and interlinks the MX2 layers, embedding specialized molecular additions to enhance their properties for energy routing, computational tasks, or structural adaptability.

-

Unison Lattice Box Extrusion: The woven MX2 stacked layers are joined and extruded out of the Unison Lattice Box. The MX2 layers and stacks emerge, ready for deployment.

Advantages of Centralized Spatial Processing

This innovative process delivers numerous benefits, including:

- Precision Manufacturing: The centralized system ensures molecular organization and interlinking at sub-micron levels, producing defect-free Chroma Spatial Processors.

- Efficiency in Production: The high-velocity extrusion mechanism allows for rapid fabrication, meeting the demands of large-scale orbital deployments.

- Customizable Outputs: By adjusting the molecular inputs and processing parameters, the system can produce Chroma Cubes tailored to specific energy, computational, or structural needs.

- Sustainability: The recycling of space debris and efficient use of MX compounds minimize material waste and reliance on Earth-based resources.

Applications

The Chroma Spatial Processors fabricated through this system serve as versatile building blocks for space infrastructure, enabling:

- Energy Management: Efficient routing and storage of energy within orbital platforms and systems.

- Advanced Communication: Enhancing data transmission and synchronization between distributed networks.

- Material Refinement: Forming the foundation for in-orbit manufacturing and resource processing systems.

- Structural Development: Providing durable, lightweight components for expanding orbital habitats and research facilities.

By combining precision, speed, and adaptability, this centralized spatial processing system turns raw materials into essential Chroma Spatial Processors, driving the evolution of sustainable space technologies.

Unison Lattice Box Bonus: Reclaimed Solar Panel Components

Beyond Chroma Spatial Processors, the Unison Lattice Box offers the capability to reclaim and repurpose solar panel materials from space debris. These materials, including photovoltaic cells and supporting infrastructure, provide an invaluable resource for generating energy in orbit, creating a tangible bonus for sustainability and innovation.

Reclaiming Photovoltaic Materials

-

Silicon Wafer Recovery: Damaged solar panels often retain intact silicon wafers. The Unison Lattice Box isolates and refines these wafers for reuse in new energy systems.

-

Conductive Metals: Precious metals like silver and copper from solar panel circuitry are extracted and repurposed for high-efficiency power systems.

-

Glass Substrate Recycling: Transparent, durable glass substrates can be repurposed for new solar modules or structural applications.

Integration into Orbital Systems

The recovered materials are processed into modular solar components suitable for integration with orbital infrastructure:

- Flexible Solar Arrays: Lightweight, durable panels for powering satellites and orbital stations.

- Energy Relays: Solar receivers for beaming energy to distant platforms.

- Supportive Structures: Recycled glass and metals serve as frameworks for orbital equipment.

Advantages of Solar Component Recovery

By focusing on solar panel reclamation, the Unison Lattice Box provides a direct benefit to orbital operations:

- Cost Savings: Reduces reliance on expensive Earth-launched materials.

- Energy Independence: Boosts energy availability for orbital systems.

- Sustainability: Minimizes waste by repurposing high-value components.

Future Potential

The reclamation of photovoltaic materials extends the versatility of the Unison Lattice Box, enabling energy self-sufficiency and fostering the development of next-generation space technologies. From powering orbital habitats to supporting deep-space exploration, this capability exemplifies the Unison Lattice Box’s role as a cornerstone of sustainable space innovation.

From Space Debris to Chroma Cubes: Precision in Zero-G

The Unison Lattice Box leverages microgravity's unique advantages to transform space debris into Chroma Cubes, establishing a sustainable foundation for space exploration.

By integrating advanced molecular refinement, electromagnetic manipulation, and additive manufacturing, the Unison Lattice Box creates modular Chroma Cubes, capable of serving as essential components for energy routing, structural adaptability, and computation.

This process not only repurposes waste but also creates an expandable platform for advanced molecular systems.

How the Process Works

- Collection: Space debris is captured using electromagnetic nets and robotic arms. In microgravity, debris is guided with minimal energy into processing chambers, where materials are sorted and stored for refinement.

- Zero-G Refinement: Microgravity enables precise molecular sorting and material purification by eliminating gravitational distortions. Refinement processes utilize electromagnetic fields to isolate and extract usable components.

- Micro-Arrangement: Molecules and particles are aligned with electromagnetic fields, creating organized configurations optimized for desired material properties and ensuring structural integrity for advanced applications.

- 3D Printing in Zero-G: Additive manufacturing processes operate in microgravity to produce defect-free Chroma Cubes, characterized by enhanced durability, conductivity, and modular functionality.

- Integration: Produced Chroma Cubes are tested and incorporated into the Unison Lattice Box system itself, expanding its operational scope and unlocking new process flows for future missions.

How Chroma Principles Shape the Process

The Unison Lattice Box draws on Chroma principles to create a streamlined, cost-effective system for producing and integrating modular components:

- Dynamic Process Flows: Chroma Cubes produced by the Unison Lattice Box serve as amplifiers for energy routing and molecular alignment, improving the efficiency of subsequent operations.

- Expandable Framework: By integrating newly produced Chroma Cubes, the Unison Lattice Box can enhance its molecular routing, energy distribution, and processing capabilities over time.

- Versatility in Output: The Chroma lattice can be customized to produce specialized cubes for energy, structural, or computational applications, supporting a wider range of future missions.

- Sustainability: Space debris is converted into reusable components, reducing reliance on Earth-based resources and creating a self-sustaining ecosystem in orbit.

Why Zero-G Micro-Arrangement Matters

Microgravity provides an ideal environment for molecular processing and additive manufacturing:

- Enhanced Purity: Without gravitational forces, impurities naturally separate, ensuring higher-quality materials.

- Precision Alignment: Electromagnetic fields manipulate molecules and particles with unmatched accuracy, forming highly organized structures.

- Superior Material Properties: Zero-G manufacturing results in fewer defects and better performance under stress, ideal for demanding space applications.

- Energy Efficiency: Materials and tools can be aligned and processed with minimal energy expenditure, reducing operational costs.

Applications of Chroma Cubes

Chroma Cubes produced in the Unison Lattice Box are designed for versatility and scalability, enabling:

- Energy Systems: Acting as dynamic nodes for energy routing and storage in space stations and vessels.

- Molecular Pipelines: Creating networks for processing and distributing gases, liquids, and other materials across orbital platforms.

- Structural Modules: Supporting the assembly and expansion of space habitats and research facilities.

- Computational Units: Functioning as high-performance processors for navigation, data analysis, and communication.

Future Expansion

As the Unison Lattice Box continues to operate, its ability to incorporate Chroma Cubes into its lattice opens pathways to even more advanced applications.

This self-enhancing process enables the development of specialized molecular pipelines, capable of transforming raw materials into refined outputs as they traverse the system.

Over time, these capabilities expand to support complex solutions such as orbital manufacturing hubs, energy relay systems, and interplanetary resource processing.

Applications of Chroma Cubes

Chroma Cubes transcend traditional material and energy management systems, offering modular solutions that redefine space infrastructure.

Each cube functions as a node for light-speed interaction, energy routing, and molecular processing, unlocking potential across a wide spectrum of applications.

When deployed as part of a distributed Chroma network, these cubes enable dynamic resource allocation, real-time processing, and sustainable expansion in zero-G environments.

How Chroma Cubes Enable Transformation

At their core, Chroma Cubes harness MX2 layers, electromagnetic control, and precise molecular pathways to create a flexible and adaptable lattice.

By routing energy and refining resources in transit, they elevate raw materials into finished goods, contributing directly to orbital and interplanetary systems.

This capability establishes Chroma Cubes as the cornerstone of a self-sustaining, scalable space economy.

Key Applications

-

Energy Systems:

Chroma Cubes act as dynamic nodes for collecting, routing, and storing energy across distributed systems.

They optimize solar power utilization, enable energy exchange via beams, and support hydrogen-based fuel production.

-

Molecular Assembly:

Within Chroma Cubes, precise electromagnetic fields align molecules for refining, bonding, or assembling into complex materials.

This capability supports applications ranging from fuel synthesis to advanced polymer production.

-

Communication Nodes:

Positioned strategically, Chroma Cubes enhance data transmission, enabling light-speed synchronization for distributed systems and vessels.

-

Structural Modules:

Modular and adaptable, Chroma Cubes are critical for building and expanding orbital habitats, research platforms, and manufacturing hubs.

-

Distributed Pipelines:

By forming pipelines of molecular refinement, Chroma Cubes transport and transform gases, liquids, and other resources, delivering ready-to-use materials to space stations and vessels.

Enabling a Self-Sustaining Space Economy

Chroma Cubes expand their functionality through continuous integration into larger systems.

As the Chroma network grows, individual cubes collaborate, processing resources at molecular scales and optimizing output for evolving requirements.

This adaptability ensures resilience in changing conditions and broadens the impact of space-based systems:

- Interplanetary Resource Management: Chroma Cubes refine and distribute resources across vast distances, supporting exploration and colonization.

- Sustainable Manufacturing: Their modular nature enables zero-waste production of critical materials and energy-efficient components.

- Energy Harvesting and Storage: By collecting and storing starlight or kinetic energy, Chroma Cubes fuel operations far beyond Earth orbit.

Future Horizons

As the Chroma Cube lattice expands, it becomes more than a network—it transforms into an ecosystem capable of supporting life, research, and innovation on a cosmic scale.

By turning challenges like space debris and limited resources into opportunities, Chroma Cubes unlock the potential for humanity's sustainable presence in space.

Energy Beams: Catalysts for Molecular Exchange and Growth

Energy beams in space represent more than a power source—they are conduits for molecular exchanges and the growth of complex systems. By harnessing starlight and directing energy precisely, these beams catalyze advanced processes that drive the space economy forward.

Gas Molecule Exchange

Energy beams enable the collection, refinement, and transfer of gas molecules:

- Targeted Exchange: Beams focus energy to move and refine molecular groups.

- Catalyzing Reactions: Heat and energy trigger molecular transformations.

- Storage and Transport: Energy-tuned fields contain gases for safe delivery.

Complex Material Assembly

Through progressive exchanges, simple molecules evolve into complex materials:

- Progressive Refinement: Hydrogen and oxygen become precursors to hydrocarbons or polymers.

- Dynamic Fabrication: Energy beams enable in-situ material creation.

Starlight Integration

Energy beams amplify and redirect starlight, turning it into a catalyst for orbital growth:

- Localized Chemistry: Beams act as micro-reactors, creating controlled environments for molecular innovation.

- Distributed Growth: Networks of beams refine and transfer resources, building sustainable orbital systems.

By transforming starlight into energy and resources, energy beams create a foundation for life support, resource redistribution, and in-space manufacturing, pushing the boundaries of what’s possible in space exploration.

Molecular Crafting in Transit: The Chroma Network

The Chroma pipeline transforms resource transportation into dynamic molecular refinement.

As molecules move between nodes, they are crafted into progressively usable forms, enabling space vessels to receive ready-to-use materials and energy.

This network not only distributes resources but also adds value at every stage.

Molecular Refinement in Transit

- Filtering Impurities: Electromagnetic fields isolate and purify target molecules.

- Purity Enhancement: Energy beams ionize or reorient molecules for specific applications.

- Isotopic Separation: Precise energy inputs segregate isotopes for specialized uses.

Transformative Molecular Crafting

- Polymer Formation: Hydrocarbons are restructured into industrial polymers or resins.

- Hydrogen Catalysis: Molecular hydrogen is refined into fuels or feedstocks.

- Alloy Precursors: Molecules are infused with trace metals for advanced materials.

Distributed Molecular Processing

Each Chroma node performs specialized tasks, leveraging energy-efficient processes:

- Localized Processes: Nodes perform distinct functions like bonding, energy charging, or structural modification.

- Energy Optimization: Minimal energy inputs maximize refinement and transformation efficiency.

- Feedback Loops: Embedded sensors adapt processes for real-time molecular refinement.

Delivering Resources to Space Vessels

- Fuel Delivery: Hydrogen or hydrocarbons fuel space vessel propulsion.

- Material Supply: Complex molecules or ready-to-use materials enable in-orbit repairs and manufacturing.

- Energy Transmission: High-energy molecules serve as portable power sources.

The Chroma pipeline elevates resource distribution into a transformative process, ensuring that every molecule contributes to the sustainability and efficiency of space exploration.

Distributed Material Ecosystem: Shared Access and Collaborative Innovation

The Chroma system represents more than just advanced material processing—it establishes a distributed material ecosystem, allowing companies, research organizations, and interplanetary missions to access and contribute to a shared pool of resources. This ecosystem supports collaborative innovation, ensures the efficient use of resources, and opens the door to dynamic space-based manufacturing.

How the Distributed Ecosystem Works

-

Shared Resource Pool: Participating entities contribute raw materials, designs, and expertise to a collective repository. This ensures a steady supply of modular components, custom materials, and Chroma Cubes.

-

Customizable Options: Organizations can select from pre-designed templates or submit their own blueprints for production. The system adapts seamlessly to specific needs, offering high precision in crafting.

-

Distributed Manufacturing: Chroma units located in different orbital hubs work collaboratively, sharing processing loads and accelerating production timelines.

-

Feedback-Driven Optimization: Embedded sensors and data-sharing protocols ensure real-time monitoring and continual improvement of production methods, reducing waste and enhancing material performance.

Benefits of the Distributed Material Ecosystem

This model offers transformative advantages for participants:

- Cost Efficiency: Shared manufacturing facilities reduce overhead, while recycled materials lower sourcing costs.

- Collaborative Potential: Organizations can co-develop solutions, pooling expertise and resources to tackle complex challenges.

- Rapid Adaptability: The modular nature of Chroma Cubes and the system’s distributed infrastructure allow for quick adjustments to meet emerging needs.

- Sustainability: Space debris is continuously repurposed, minimizing reliance on Earth-based resources and supporting a circular economy in orbit.

Examples of What Can Be Ordered

Organizations can order a wide range of components and solutions tailored to their missions:

- Energy Systems: Self-healing solar arrays, energy storage units, or conduits optimized for orbital applications.

- Structural Modules: Lightweight lattice frameworks, modular station expansions, or customizable research platforms.

- Material Kits: Ready-to-assemble molecular pipelines, alloy precursors, or polymer crafting packs.

- Precision Tools: Specialized manufacturing tools for orbital assembly or resource refinement.

How to Access the Ecosystem

Participation in the distributed material ecosystem is simple:

- Browse Resources: Access the global Chroma repository to view available materials, components, and templates.

- Submit Requests: Order pre-fabricated components or upload custom designs for on-demand production.

- Receive and Integrate: Completed orders are delivered directly to the requesting organization’s orbital location, ready for integration into their systems.

A Flexible and Adaptive System

As the ecosystem grows, it becomes a hub of innovation, fostering collaboration between organizations and enabling the creation of increasingly advanced technologies. Whether supporting deep-space exploration, building orbital habitats, or advancing interplanetary research, the Chroma distributed material ecosystem is designed to empower humanity’s reach into the cosmos.

<= Back

<= Home (Splash)