Introduction

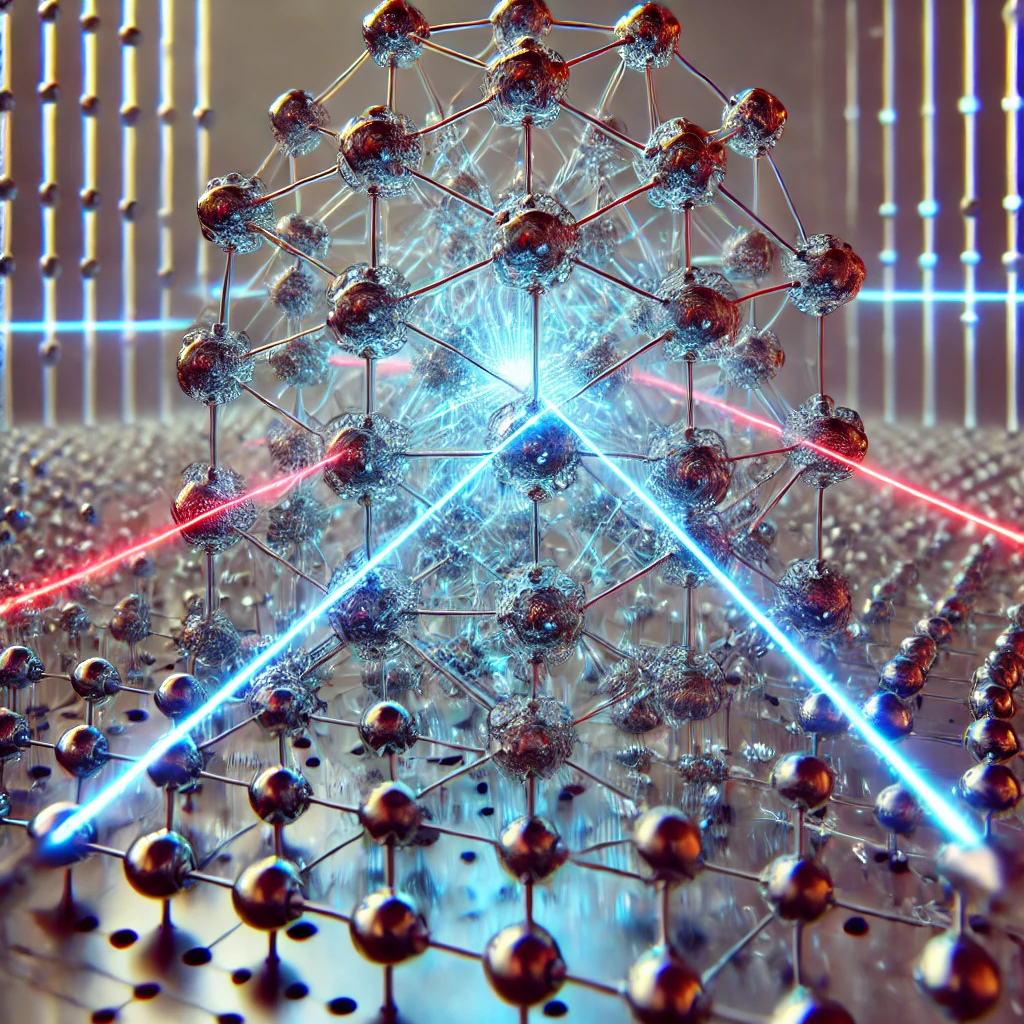

The Molecular Factory System represents a groundbreaking approach to material synthesis, combining atom lasers and lattice-based architectures to achieve unparalleled precision. By directing molecular bonds with atomic-level coherence, this system enables the creation of advanced materials with minimal energy waste.

Atomic Guidance

At the core of the Molecular Factory is the use of atom lasers to guide and manipulate molecular bonds. These lasers:

- Precisely Align Bonds: Direct atoms to bond in desired configurations, ensuring material uniformity.

- Reduce Errors: Minimize bond misalignments that could weaken the material structure.

- Create Tailored Structures: Enable the synthesis of complex molecular architectures tailored for specific applications.

Energy-Efficient Synthesis

The lattice-based assembly process within the Molecular Factory minimizes energy waste by:

- Targeted Energy Use: Energy is directed precisely where it is needed, avoiding unnecessary dissipation.

- Dynamic Feedback Loops: The system adapts in real time to ensure optimal energy flow and material consistency.

- Scalable Production: Materials can be synthesized efficiently at both small and large scales.

This energy-efficient approach makes the Molecular Factory ideal for sustainable manufacturing in resource-constrained environments.

Applications

The potential applications of the Molecular Factory System are vast and transformative:

- Drug Design: Create precise molecular compounds for pharmaceuticals with minimal impurities.

- Self-Healing Materials: Engineer materials that can repair themselves by re-aligning molecular bonds.

- Spacecraft Assembly: Manufacture lightweight, durable materials tailored for interstellar environments.

- Quantum Devices: Fabricate materials optimized for quantum computing and advanced electronics.

Future Prospects

The Molecular Factory System is poised to revolutionize manufacturing by enabling:

- Universal Manufacturing: Synthesize any material by programming atomic configurations into the system.

- Localized Factories: Deploy compact, portable units capable of manufacturing materials on-site, reducing supply chain dependencies.

- Interplanetary Construction: Use local resources on other planets to create infrastructure and tools.

As the technology advances, the Molecular Factory could become the cornerstone of a new era in material science, where precision, efficiency, and adaptability are the norm.

Atomic Guidance with Atom Beams

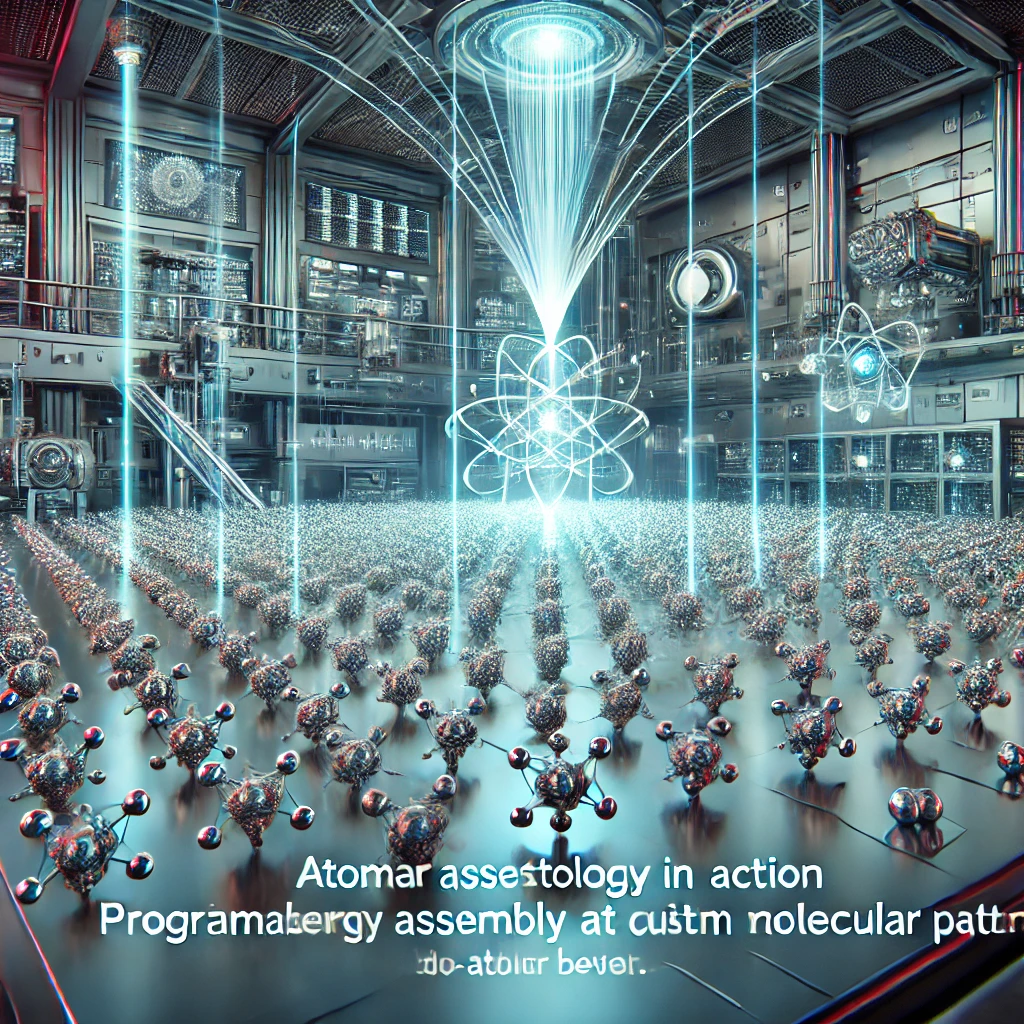

The core innovation of the Molecular Factory System is the Atom Beam, a revolutionary technology inspired by the precision of CRT displays and the foundational principles of atomic lasers. Atom Beams act as molecular "printers," directing energy streams to assemble materials at the atomic level with unparalleled accuracy.

- Precision Bonding: Atom Beams align molecular bonds with sub-atomic accuracy, ensuring perfect material integrity.

- Dynamic Control: Real-time adjustments in beam intensity and direction allow for complex molecular assemblies.

- Programmable Assembly: Atom Beams can be programmed to create custom molecular patterns for tailored applications.

This approach transforms the molecular factory into a versatile system capable of producing any material by projecting the right atomic pathways.

Advantages of Atom Beam Technology

The Atom Beam elevates molecular assembly to new heights by introducing:

- Enhanced Efficiency: Atom Beams minimize energy waste by focusing energy only where it is needed.

- Rapid Prototyping: Assemble complex materials faster than ever, enabling quick iterations for innovation.

- Scalable Systems: Atom Beams can be deployed in arrays, scaling production for industrial and cosmic applications.

Future Potential: From Atom Beams to Universal Factories

Atom Beam technology opens the door to universal manufacturing systems capable of:

- Energy Streamed Atomic Assembly: Streamlining material synthesis through direct energy-to-structure transformations.

- Distributed Factories: Deploying compact molecular assembly units for on-demand manufacturing in space or remote locations.

- Cosmic Resource Utilization: Harnessing extraterrestrial materials to create sustainable infrastructure for interstellar missions.

By integrating Atom Beams into the Molecular Factory System, we envision a future where manufacturing is no longer constrained by geography, resources, or energy limitations.

Conclusion

The Molecular Factory System is more than a technological innovation; it is a vision for the future of material science. By combining atom lasers with lattice-based assembly, it offers a sustainable, efficient, and precise method for creating the materials of tomorrow.

<= Back

<= Home (Splash)